MicroDry®️ ALL-IN-ONE es un sistema patentado de lubricación y limpieza en seco para transportadores mecánicos, que se utiliza en las industrias de bebidas, lácteos y cervezas.

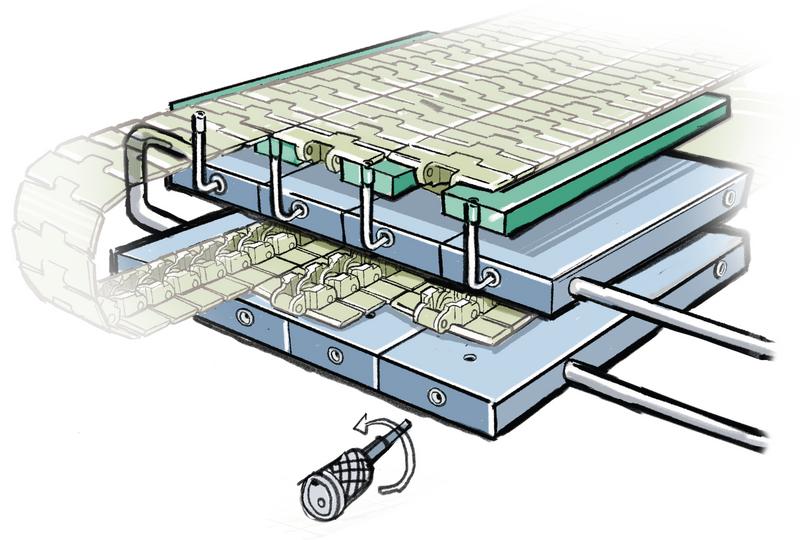

En cuanto a la lubricación, MicroDry®️ AIO es un sistema hecho a medida que se integra en el lado de retorno de la cinta transportadora y lubrica la parte superior y la inferior. El sistema de limpieza modular, CLUDLU-5500, limpia el interior y el exterior (lavado de cinta).

Ambos sistemas se instalan en pocos días. Son compatibles con todos los modelos y marcas.

El exclusivo sistema de lubricación superior e inferior extiende una capa microscópica de lubricante DLT-333®️ para minimizar la fricción y evitar los problemas de sacudidas.

El sistema para limpiar el transportador ofrece limpieza semiautomática o completamente automática, y por secciones. El aclarado, la espuma, la activación y la desinfección opcional se optimizan por secciones.

Es sorprendente que una gota tan pequeña pueda producir un efecto tan grande. Sencillo, pero inteligente.

Podríamos haber ahorrado tiempo y dinero si hubiéramos optado directamente por el Seco en lugar del semiseco.

Estamos evaluando las ventajas del sistema para introducir MicroDry en nuestras plantas de todo el mundo.

La unidad de limpieza CLUDLU-5500 está diseñada para optimizar el proceso de todas las secuencias de limpieza para minimizar el tiempo total.

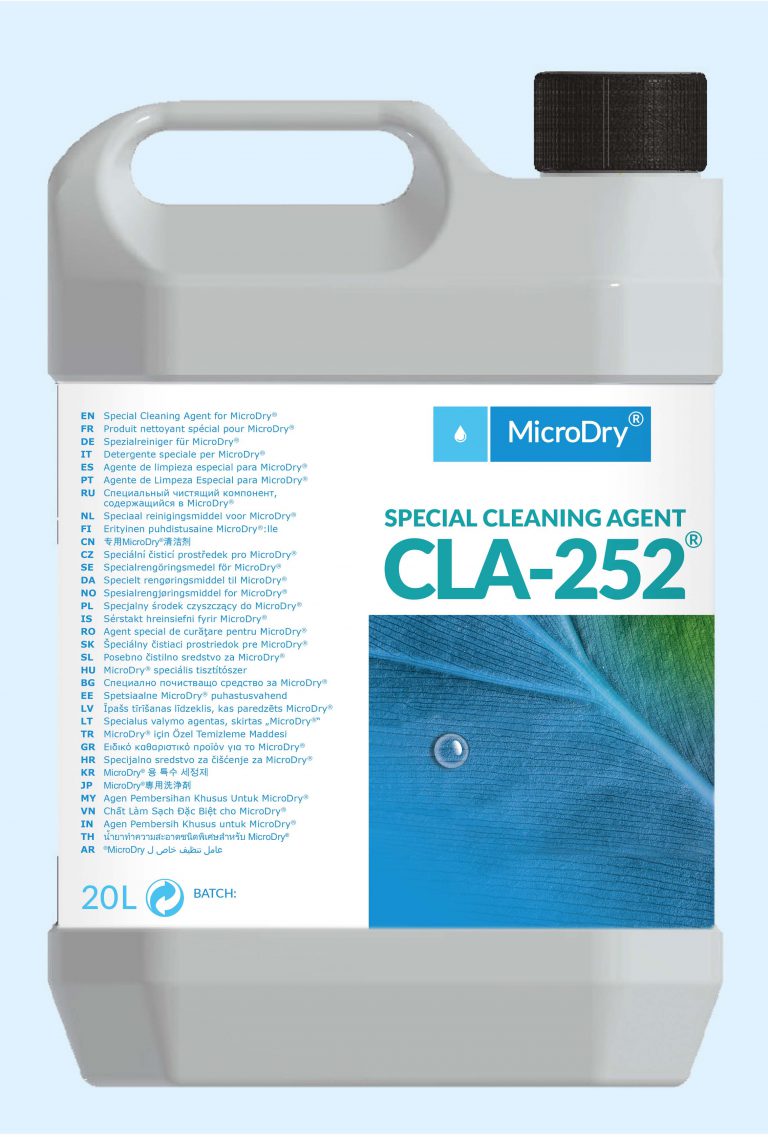

CLA-252 es nuestro espumante altamente eficaz para desengrasar y eliminar restos derramados, diseñado especialmente para CLUDLU-5500.

La limpieza interna y externa de cada cinta proporciona un mayor de nivel de descontaminación que la limpieza solamente interna.

La línea completa se puede dividir en zonas con diferentes requisitos de frecuencia de limpieza; a la medida de las necesidades específicas.

Las boquillas específicamente diseñadas reducen el consumo de agua que se necesita para lograr el nivel de descontaminación necesario.

El sistema de lubricación MicroDry®️ reduce la fricción, las paradas imprevistas de la línea y la presión de retorno en transportadores mecánicos, mejorando consideradamente la eficiencia general de la línea.

CLA-252®, un limpiador sumamente eficaz

CLA-252 es un desengrasante espumante para la limpieza del transportador, elimina los restos derramados de alimentos, bebidas y sustancias oleosas.

Es un limpiador biodegradable y compatible con los materiales que se utilizan habitualmente en la industria de alimentación y bebidas.

MicroDry®️ es una tecnología avanzada y sostenible de lubricación en seco a medida para transportadores, desarrollada y patentada por CHP.

CHP es una empresa de ingeniería líder en diseño, fabricación, instalación y mantenimiento de innovadoras soluciones de lubricación de última generación, que van desde instalaciones a pequeña escala hasta grandes proyectos llave en mano. Somos una empresa belga muy apreciada entre los clientes internacionales a los que abastecemos desde hace 20 años.

Diseñamos y fabricamos una innovadora solución de recubrimiento hecha a medida que responda a su necesidad de un sistema de recubrimiento seco superior, rentable y sostenible.

Realizamosla instalación en planta. La instalación, la puesta en servicio y el arranque pueden realizarse consecutivamente o en intervenciones separadas, dependiendo del calendario general del proyecto.

Nuestro departamento de ingeniería ofrece un día de formación in situpara que los participantes adquieran conocimientos básicos del principio de funcionamiento, la monitorización y la solución de problemas.

Nuestro equipo de servicio siempre está disponible para ayudar en el mantenimiento correctivo y para ejecutar cambios menores en la planta.