MicroDry® All-In-One is a patented dry lubrication & cleaning system for mechanical conveyors, used in the beverage, dairy and brewery industry.

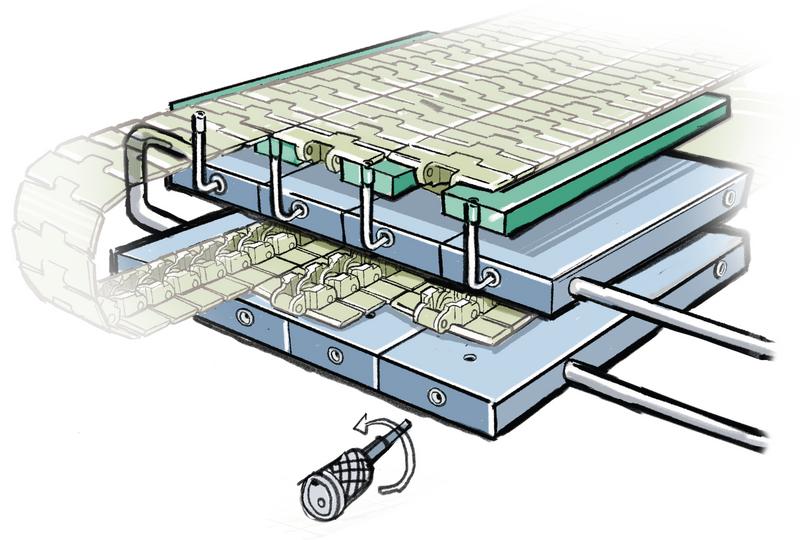

As for the lubrication, MicroDry® AIO is a custom-made conveyor lubrication system, integrated at the return side of the conveyor belt. The modular cleaning system provides internal & external cleaning (or belt washing).

Both systems are installed within a few days. Suitable for all brands and types.

The unique top & bottom conveyor lubrication system diffuses a microscopic thin layer of our DLT-333® lubricant to minimize friction and avoid stick-slip issues.

The conveyor cleaning system offers a semi-automatic or a full automatic and sectionalized cleaning. Rinsing, foaming, activation & optional disinfection are custom optimized per section.

Our automated cleaning control unit is designed to optimize the processing of all cleaning sequences, to minimize your total cleaning time.

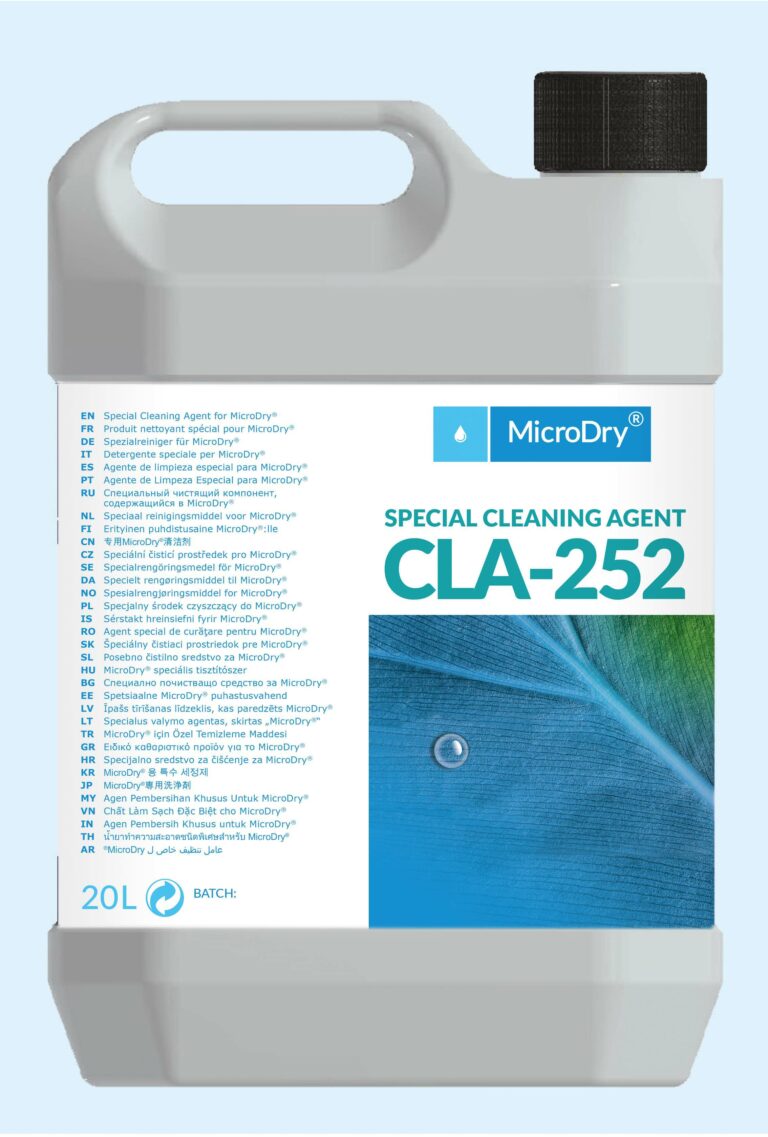

CLA-252 is our high effective degreasing and spillage-removing foaming agent, specially designed for our MicroDry® conveyor lubrication and cleaning solution.

Internal and external cleaning per conveyor belt will increase the level of purity of the belts, compared to only internal cleaning systems.

Your conveyor line can be split into zones that need different cleaning frequencies; cutom to the needs of the line.

The specific designed nozzles will reduce the water consumption needed to achieve highest purity level on your conveyor belts.

MicroDry® Slat reduces friction, unforeseen line-stops and back-line pressure on mechanical conveyors, considerably improving your line efficiency.

CLA-252, a high performing cleaning agent

CLA-252 is our degreasing foaming agent for conveyor cleaning, to remove spillages of food, beverages and oily substances.

Our cleaning agent is biodegradable, and compatible with most commonly used materials used in the food & beverage industry.

Learn more about MicroDry®, a sustainable advanced custom-fit technology with minimal operating cost, developed & patented by CHP to meet the customers conveyor lubrication/coating needs.

CHP is a leading engineering company designing, manufacturing, installing and servicing innovative state-of-the-art coating and conveyor lubrication solutions, ranging from small-scaled installations up to large turnkey projects. We are a Belgian company, successfully supplying to a wide range of international customers for the past 20 years.

We design and manufacture your custom MicroDry® conveyor lubrication, coating and cleaning technology.

We perform on-site installation by our in-house skilled technicians.

Our engineers provides a one-day in-house training about our conveyor lubrication or cleaning solution.

Our servicing team is always ready to maintain your MicroDry® conveyor lubrication, coating or cleaning system.