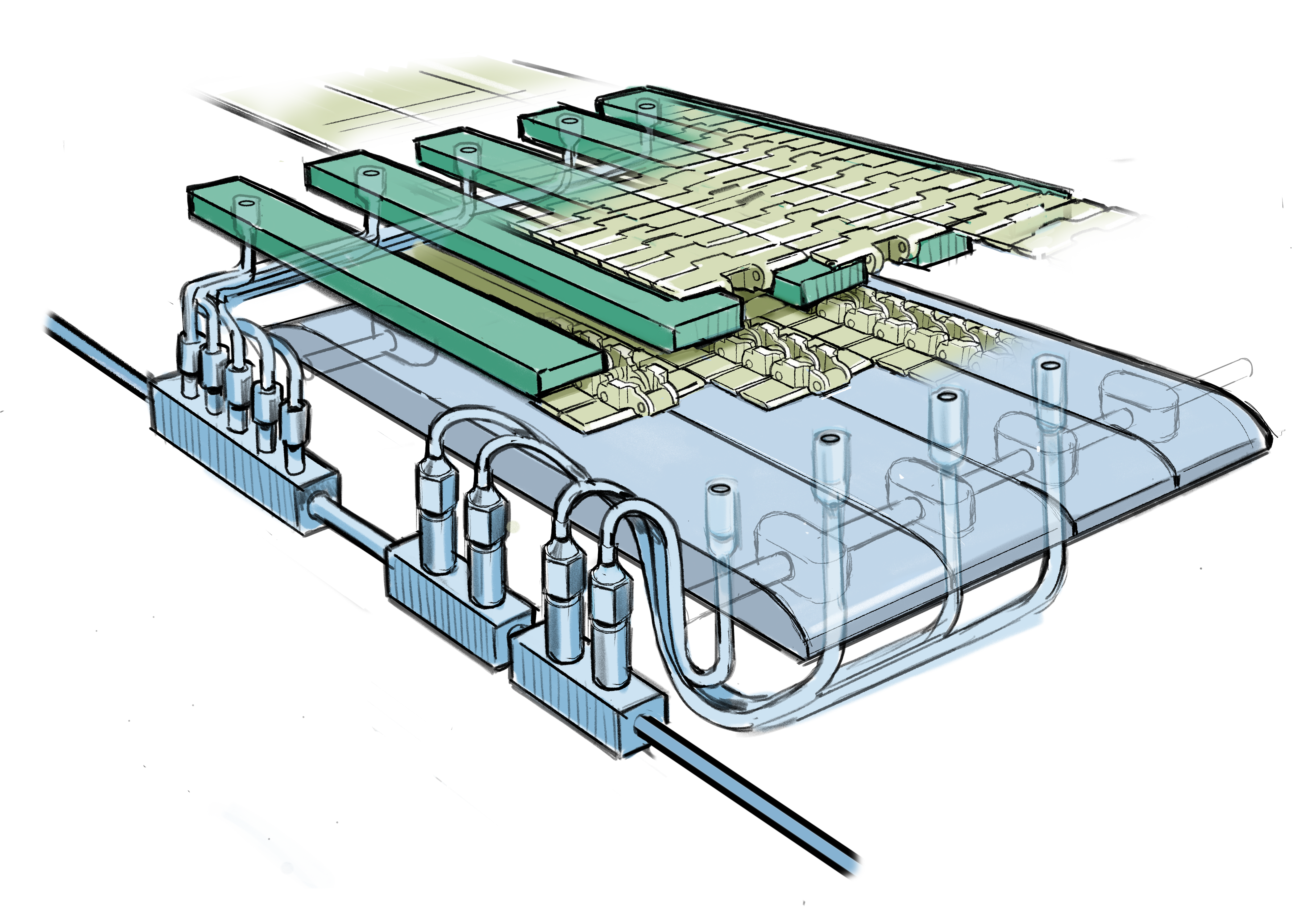

MicroDry®️ SLAT 是获得专利的机械式传输机干式润滑系统,广泛应用于饮料、乳制品和酿酒行业。其主要应用于硬纸板生产线、装瓶线和罐装线,同时也应用于罐子和板条箱传输机。

将几天内安装的定制顶部和底部润滑系统集成到输送带的返回侧。适用于所有品牌和类型。

无刷子或喷嘴。这种独特的顶部和底部润滑系统将涂抹一层薄薄的微观 DLT-333®️ 润滑剂,以最大限度地减少摩擦并避免传输机粘滑问题。

全自动化控制器系统优化了关键区域的润滑效果。

小小一滴竟然有如此显著的效果,真是令人赞叹。 简单而智能!

如果我们当初直接使用全干式而不是半干式系统,就可以节省一些时间和费用。

我们评估了该系统的优势,以在我们全球的工厂中推出 MicroDry。

使用 MicroDry®️ SLAT,

一条普通的纸箱包装线外加 8 个单独的履带传输机蓄能器和打包器,每年只需施加 25 升 DLT-333 润滑剂。

全自动控制器系统的刷子或喷嘴无需维护。

彻底告别湿滑的地板,因为不再有水、涂料或产品溢出

所用润滑剂都可生物降解,且 100% 无水无硅。

此外,MicroDry 降低了能源消耗,支持使用水和洗涤剂,从而减少了生态足迹。

MicroDry 是经 FDA 批准的产品,不会有细菌和真菌滋生。

MicroDry 还有一款可选的全自动集成清洁系统可用于您的输送带,即 MicroDry ALL-IN-ONE。

极低的消耗

以及超过

18 个月的保质期,可简化您的物流。

干式润滑剂可精确均匀涂抹,从而可为您节省 10% 到 15% 的能源成本。

得益于已涂层的机械式传输机,输送带和防磨带的使用寿命最高可延长 3 倍。

MicroDry®️是 CHP 开发的专利技术,是一种先进、可持续的定制技术,拥有最低的运行成本。

CHP 是一家致力于设计、制造、安装和维护创新型先进润滑解决方案的领先工程公司,涵盖小型装置到大型统包工程等各类业务。我们是一家比利时公司,过去 20 年成功为大量国际客户提供解决方案。

我们将设计并制造出创新型定制润滑解决方案,以满足您对卓越、高性价比且可持续的干式润滑系统的需求。

我们会进行现场安装。安装、调试和启动作业可以背靠背或单独进行,具体取决于整体项目进度。

我们的工程部将提供为期一天的内部培训,使参与人员对工作原理、监控和故障排除有基本了解。

我们的维护团队随时可以协助进行维修保养和进行较小的设备变更作业。